Use of tailings

Since 2005, Samarco has been studying options for recycling the tailings resulting from the beneficiation of iron ore. This aspect of mine waste management is one of the pillars of Samarco´s ongoing strategy to resume its operations.

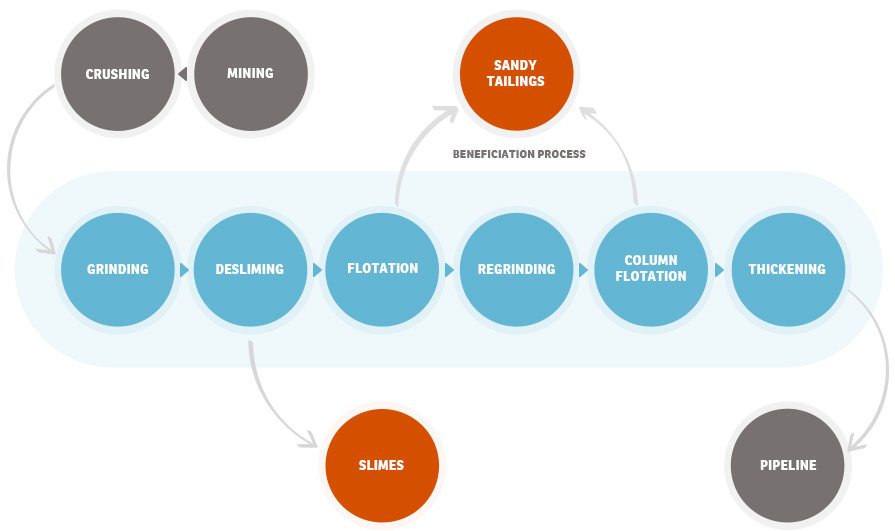

Below you can see how the tailings, both sandy and slimes, are generated during the process:

Iron ore tailings applications

The tailings that are left over from the iron ore beneficiation process are formed of iron ore, sand and water. They are not toxic, corrosive or flammable.

Samarco’s process results in two types of tailings – sandy tailings and slimes. Depending on their chemical and physical characteristics, these tailings can serve as raw material for the development of other products.

As examples we have cement tiles, precast blocks, ceramic products, ferric salts, among others.

Interlocking blocks

In 2013 and 2014, interlocking blocks with a 30% content of Samarco´s sandy tailings were used for paving in the district of Porto Grande, in the City of Guarapari, Espírito Santo, as well as at the Company´s industrial facilities.

Plastic wood

Benches made of so-called plastic wood using tailings slimes are scattered throughout Samarco´s units. The slimes were used as a pigment, which, being inorganic, is considered more durable for coloring the material produced with recycled plastic and wood fiber.

Projects we support

MinerALL Challenge

The MinerALL Challenge is a Samarco initiative in partnership with the accelerator Neo Ventures and with the support of the Federal University of Ouro Preto (UFOP), Federal University of Minas Gerais (UFMG), National Institute of Science and Technology (INCT MIDAS), and Center of Development of Nuclear Technology (CDTN). Launched in 2018, the goal of the first edition of the Challenge was to transform the various technologies for use of tailings into business opportunities.

The first edition of the Challenge was exclusively focused on the use of Samarco tailings (sandy and slimes) in other industrial sectors, based on the pre-acceleration of technologies. This required the participants to carry out technical, socio-environmental and economic feasibility studies supported by methodology, mentoring, training and interactions with recognized professionals.

In addition to rethinking applications for tailings, the challenge also aims to support the economic diversification of the municipalities of Ouro Preto and Mariana and strengthen the ecosystem of innovation and entrepreneurship, focusing on solutions with socio-environmental impact.

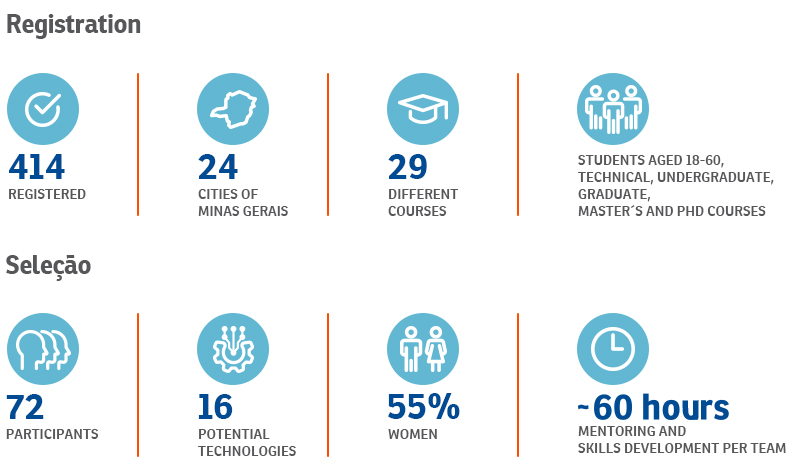

See below the main Challenge numbers and the video of the initiative:

Registration

Mining Hub

Launched in January 2019, the Mining Hub is the world’s first mining hub and was created to be a direct channel for innovation, social projects, industry trends and the relationship between miners and startups. Headquartered in the WeWork building in Belo Horizonte (MG), Mining Hub is an environment created to generate opportunities and connections with suppliers, startups, researchers or investors interested in the mining sector.

One of the main initiatives of the hub is M-Start, a program aimed at connecting innovative initiatives with accredited miners, such as Samarco, to develop multi-themed solutions such as operational efficiency, alternative energy sources, water management, waste management and safety. With a duration of 4 months, the program evaluates the applicability of the initiatives and carries out concept testing with each of them to verify the possibility of implementation.

BeGreen

In 2017, Samarco entered into a partnership with BeGreen, the first urban farm in Latin America, located in the Boulevard Shopping Center in Belo Horizonte.

The interlocking pavers on their floor were made using Samarco’s sandy tailings. These paving blocks, manufactured by Uni-Stein, offer the same safety and durability as the blocks made with only sand and aggregate, in addition to being more eco-friendly.

Samarco also supplied the tailings slimes for the production of the plastic wood used to make the decks, tables and chairs in this space, fabricated by the company Ecoblock, which also participates in this initiative with Samarco together with Uni-Stein.

See more in the video below: