Dams

Samarco maintained, until November 5, 2015, two dams for the storage of tailings resulting from the extraction and processing of iron ore at its Germano (MG) plant. The newest one was Fundão, inaugurated in 2008, with storage of 55 million cubic meters.

The dams were built in line with the National Dams Security Policy (Law 12.334 / 2010), with its own safety inspections and 24-hour shift teams for maintenance and monitoring. Operating licenses were regularly granted by the Regional Superintendence of Environmental Regulation (SUPRAM) – the last inspection before the disruption was carried out in July 2015. In September of that year, reports were delivered to the competent authorities, indicating a safe operational condition for the dams. Regrettably, even with the risk management procedures associated with dams, these measures were not able to anticipate the disruption.

Through the rupture of the dam, Samarco executed its Samarco Mining Dams Emergency Action Plan, presented to the National Department of Mineral Production (DNPM), and Germano’s production process was immediately interrupted.

There were two embargoes on Germano: one from the DNPM, on the operations of the dams and UTM treatment units, and another from the State Foundation for the Environment (Feam) together with the Secretary of Environment and Sustainable Development (SEMAD) , On operations as a whole, except for activities considered emergency (such as structural reinforcement works). In the unit of Ubu, in Anchieta (ES), there was no embargo due to the rupture.

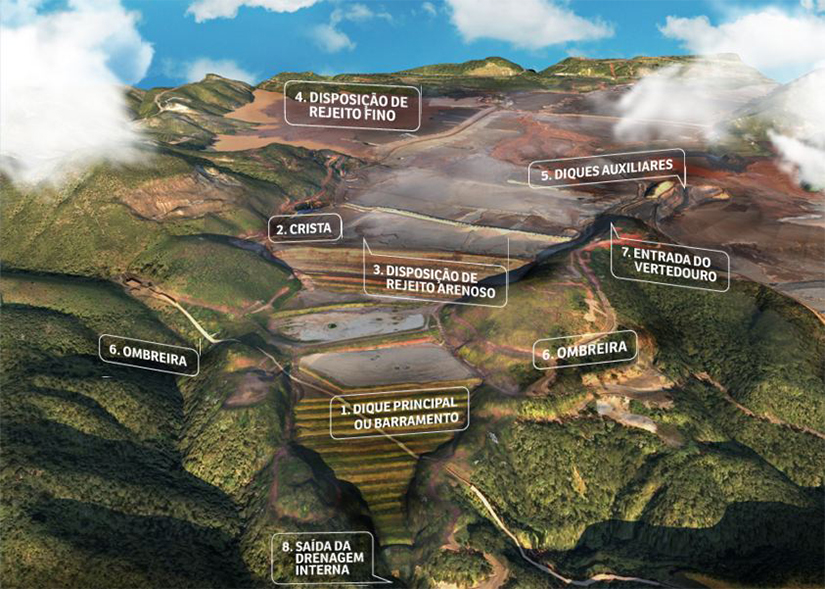

Understand what are and how the structures of a dam work:

In the process of iron ore beneficiation, the material extracted during mining is separated – the ore is directed to the production of pellets, while the mixture of water, together with particles of iron oxide and silica or quartz (the tailings), is disposed of.

As the tailings are deposited in the dam, the solids settle to the bottom and the water comes to the surface. The water is then drained or skimmed off and treated, with part of it being reused in the beneficiation process and the rest returned to the environment.

The tailings mixture does not contaminate the water nor does it represent a hazard to human health. Learn more about the composition of the tailings in this video: